About Pickup Parts

What is Pickup Parts?

The Pickup Task in Request Management is used to execute the pickup of material required for service work prior to arriving at the work location. It displays the material that needs to be picked up from a supplier or from a warehouse, the pickup date, and the assignee responsible for performing the task.

Pickup Tasks can be used to receive Inventory Parts as well as Non-Inventory Purchase Parts and No Part lines from the Purchase Order.

Explanation

Pickup Task creation

- For material planned on the Work Task, if the supply code is set to Purchase Order or Shipment Order together with the delivery method Pick Up, the material lines are eligible for pick up. Material to be purchased from a supplier can be picked up from the supplier’s location, while material delivered via a Shipment Order can be obtained from the site’s warehouse.

- Pickup Tasks are created when releasing material lines. Material line release happens when the Work Task is Released.

- New Pickup Tasks will be created in the Released state.

- For a single work task, many Pickup Tasks can be created based on the pickup location and logistic site.

- For the creation of a Pickup task, the user should have access to the logistic site. However, at the point of creating the Pickup task, the service access groups of the source work task will be copied to the Pickup task, enabling users in those access groups to view the pickup task. It's important to note that even though a user has access to the pickup task, they must also have access to the logistic site to process the pickup task.

Dependency to Work Task

- When a Pickup Task is created, a predecessor dependency to the work task is automatically created, to ensure that the pick up is scheduled and executed before the main work task.

- If the Ignore Dependency in Execution is set to Enabled on the main Work Task, and the Pickup Task is connected to the main Work Task, both can be transferred to the mobile.

- It is not possible to change both the Set Dependency flag and the Ignore Dependencies flag.

- The dependencies of the Work Task will be available on the Work Task Dependencies page. The Pickup Tasks from the selected Work Task and other Work Tasks present in the scope are shown on this page.

Grouping of Material Lines

If the Work Task is in status New and the task has multiple material lines with the delivery method Pick Up, the same supplier if the Supply code is Purchase Order and the same warehouse if the Supply code is Shipment Order then,

- One Pickup Task will be created with multiple Pickup lines when releasing the Work Task. The Pickup Task and all Pickup lines will be consolidated to one Purchase Requisition or one Shipment Order.

- When adding new material lines for the Released Work Task, separate Pickup Tasks will be created for each material line.

Pickup Address

- The Pickup Address states the address from which the material needs to be picked up.

- For material purchased from a supplier (Supply code: Purchase Order), the Pickup Address will be fetched from the supplier's default visit address.

- For material obtained via a shipment (Supply code: Shipment Order), the Pickup Address will be set from the Main Warehouse defined on the Site/Maintenance page, for the logistic site of the material planned on the work task.

Pickup Date

- For Shipment Orders: The Pickup Date corresponds to the Promised Delivery Date of the shipment order lines. This date is updated when confirming or modifying the delivery date in the Shipment Order.

- For Purchase Orders: The Pickup Date is based on the Promised Delivery Date of the purchase order lines. If there are multiple purchase order lines with different dates, the latest date is used as the Pickup Date. This date is fetched when the Purchase Order is confirmed.

Pickup Duration

The Pickup Duration displays the time required to pick up the material. The default pickup duration is set from the Pickup Duration defined on the Site/Maintenance page for the logistic site set on the material. The duration can be changed on the individual pickup task if needed, and the value is in Minutes.

Pickup Lines

The Pickup Lines displays the list of material lines from the work task that needs to be picked up on this particular pickup task. Changes done to material lines on the work task (e.g, updating quantity required) will be reflected on the pickup lines.

Resource Demand

- The Resource Demand displays the first demand line of the main Work Task, if Resources exist on the main Work Task when creating the Pickup Task.

- If a Resource demand line is planned on the main Work Task after the Pickup Task has been created, and no resource demand lines exist on the Pickup Task, the first demand line will be fetched to the pickup task.

- When copying the Resource demand to the Pickup Task, quantity is always set to One.

Assignee

The Assignee displays the Work Assignment that is created through Assign work on the Pickup Task. The Allocations on Resource Demand and Direct Allocation can be used to assign a work. Only one work assignment is used to execute the Pickup Task. The assignee for both the pickup task and the source task must be the same in order to execute the pickup task and issue the materials on the source task in MWO.

Scheduling Info

Displays information related to automatic scheduling, such as Scheduling SLA Types, Availability, Region, Preferences, and Allocations.

It is possible to specify Availability, Preferences and region details according to requirements and these details will be sent to the Scheduling Engine. Once the activity(s) for a work task are scheduled by the Scheduling Engine, an allocation plan with the current scheduling status, resource assignment, and activity start and finish dates will be displayed in the Allocations section.

When the Pick up task is created, the scheduling dataset of the source request work task is copied to the pick up task and the scheduling dataset is automatically updated on pickup task when it is updated on the source request work task as long as the status of the pick up task is Released.

Execute Pickup Task

This section explains the execution process for pickup tasks in the mobile client. A pickup task is synchronized with the source task that includes the planned pickup materials.

Users can obtain the material from either a delivery warehouse or a supplier location. MWO enables users to complete the pickup activity and receive parts into the mobile user warehouse in a single operation.

Note: Pickup functionality is supported exclusively in the IFS Request Management solution and is available only within MWO Service Management.

Prerequisites

- A default location must be defined with the location type Picking for the user’s connected remote warehouse. Mobile users can set this up in Warehouse Management/Location/Warehouse Navigator/Warehouse/Remote Warehouse before executing the shipment pickup task.

- The Automatic Receipt flag must be set to True for the shipment type assigned to the user’s logistic site. This can be configured in Shipment Management/Outbound Shipment/Basic Data/Shipment Type/Shipment Order.

Sync to MWO

After the source task is transferred to the mobile device, both the source task assignment and the pickup assignment are synchronized to the device.

To sync the part order lines associated with the pickup task, ensure that the following batch entities in Solution Manager/Mobile Apps/Configuration/Synchronization Rules are synchronized:

- For Shipment Pickup order lines: ShipmentOrderLine

- For Purchase Pickup order lines: PurchaseOrderLineAllQuery

Find My Pickup Assignment in MWO

- Pickup assignments can be located in both the My Work list and My Work Calendar. The source task assignment will be labeled as Has Pickup Task, while the pickup task itself will be labeled as Pickup Task.

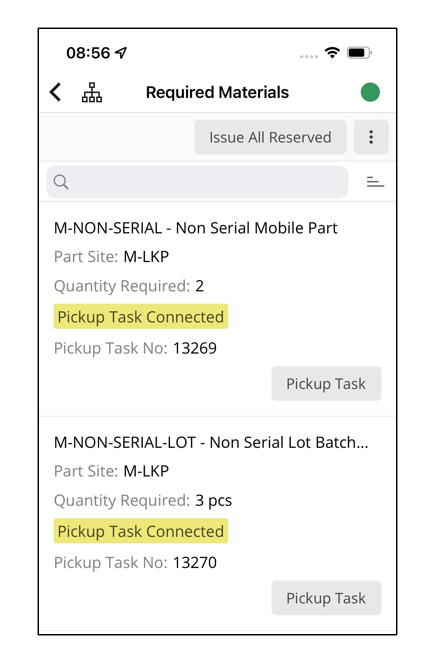

- Users can also navigate to the Pickup assignment from the Required Materials screen of the source task.

- Users can access the details view of a Pickup assignment to view more information.

- In the work details view for the pickup task, the mobile technician can find key information, including:

- Pickup Location: The location where the pickup is to be performed.

- Pickup Date: The scheduled date for the pickup.

- Ready To Be Picked Up Flag: An indicator showing whether the items are ready for pickup.

This detailed view helps ensure that all necessary information is available for the mobile user to perform the task effectively.

Ready To Be Picked Up

- For Shipment Orders: The Ready To Be Picked Up flag is set to True when the Shipment header is marked as Complete.

- For Purchase Orders: The Ready To Be Picked Up flag is set to True when the Pickup Date is earlier than or equal to the current device time.

Processing of Pickup Assignments in MWO

The behavior for processing pickup assignments differs slightly between shipment orders and purchase orders:

- For Shipment Orders: The shipment is completed by simply completing the pickup assignment. The mobile users can only start pickup assignments for shipment orders if they have a default inventory location set up under the remote warehouse.

- For Purchase Orders: The mobile user needs to manually receive the material to enable partial receipt of picked-up parts. This can be done through the Part Pickup action within the pickup assignment.

Pickup Assignment Statuses

Pickup assignment statuses are handled like Normal work tasks. Below are the statuses and the system effects associated with each status change:

- Cancel: The pickup assignment is marked as Canceled. The source task can be processed without considering the pickup material demands.

- Accept: The pickup assignment is set to accepted.

- On Route: The technician is expected to start travelling if the Ready To Be Picked Up flag is set to true. If not, the system will prompt an inquiry, but the user is still allowed to start the pickup assignment if needed.

- Work Start: The pickup assignment is set to started.

- For Shipments: The Receiver ID is updated in the shipment to the user's default remote warehouse, and the default warehouse location is set as the part receive location.

- For Purchases: The user's default remote warehouse is used as the destination warehouse in the purchase order lines.

- Incomplete: The pickup assignment is marked as incomplete. The source task can still be processed.

- Complete: The pickup assignment is marked as complete, and the pickup task is set to Picked Up status. The shipment will be delivered, and the shipment and shipment order will be closed in the back office. Parts that have shipped are updated as reserved materials in both Inventory Part In Stock (back office) and My Stock (mobile).

Receive Picked-Up Parts in MWO

Shipment Orders

- Completed shipment lines should be synchronized to the mobile device via the batch entity ShipmentOrderLine.

- The receipt of materials into the mobile user’s warehouse is automatically handled upon the completion of the pickup assignment.

Purchase Orders

- Materials picked up from the supplier should be received into the user’s warehouse.

- Purchase receipt lines of released or confirmed purchase orders should be synchronized to the mobile device via the batch entity PurchaseOrderLineAllQuery.

- The receipt of materials into the location of the user’s connected warehouse can be done manually.

After Receiving Picked-Up Parts

Once the picked-up parts are received, they will appear under Reserved Materials on the main task.

Note: The execution flow for Pickup Tasks in the mobile application is supported offline.

Time Zone Handling

All timezone-related date-time fields in IFS Cloud are stored in either the Site timezone or the Server timezone. In the Pickup Task, the date-time will be stored in the time zone of the Time Zone Site of the Service Organization and displayed to the user in the same time zone. The Time Zone badge can be enabled from the Time Zone group in the IFS Cloud Account Settings so that the time zone details will be visible when the user hovers over the badge, and the time can be viewed in UTC time as well. UTC Time - the standard used to establish time zones worldwide. UTC+00:00 is used as an identifier from which all the other time zones are derived. For example, New York (EDT) is UTC -4.