View & Manage FMECA Analysis

Results & Observation

Use this dashboard to view and manage the FMECA Analysis based on the FMECA Analysis results and requirements. The FMECA Dashboard page includes the following elements: PM/CM Ratio, Maintenance Cost, Most Used Fault Types, and Object Details.

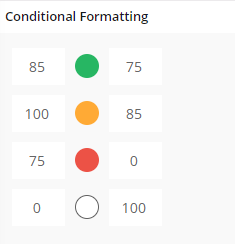

The PM/CM Ratio element represents the ratio between Preventive Maintenance and Corrective Maintenance strategies for a given Item Class and Process Class combination.

A PM/CM ratio of 85 -100 means the object has many Preventive Maintenance actions and less Corrective Maintenance actions, raising questions about the high number of Preventive Maintenance actions.

A PM/CM ratio of is between the range of 0 -75 indicates many problems, as there are few Preventive Maintenance actions but many Corrective Maintenance actions, requiring investigation into the lack of Preventive Maintenance actions.

A PM/CM ratio between 75 - 85 is ideal, indicating a good balance between Preventive and Corrective Maintenance.

The Maintenance Cost element represents the cost of the objects, defined in the Work Order and visible on the Object Cost Analysis page. Based on the cost, decisions are made about whether to conduct the FMECA Analysis.

The Most Used Fault Types element represents the most common Failure types reported via Work Orders (WOs). These fault types need to be considered when performing the FMECA to ensure comprehensive and effective maintenance strategies.

The Object Details element includes the open anomaly count and reported anomaly count for a particular item class and process class combination of objects and also indicates if the FMECA analysis has been performed on that object.

Prerequisites

N/A

System Effects

N/A